State-of-the art technology

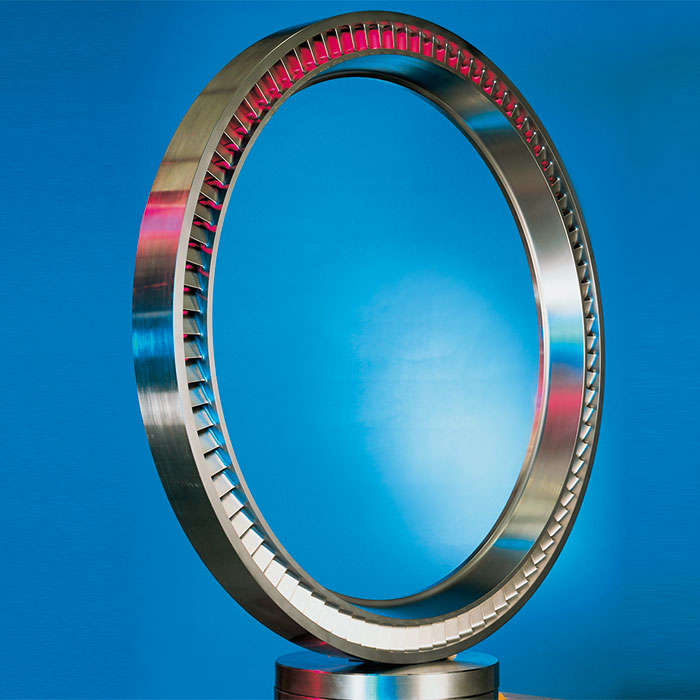

Contrary to conventional welding technology, the manufacturing of an EDM ring nowadays requires only three manufacturing steps:

![]() 1. Pre-milling

1. Pre-milling

![]() 2. EDM-finishing of the channel and profile contours

2. EDM-finishing of the channel and profile contours

![]() 3. Polishing of the channel and profile contours

3. Polishing of the channel and profile contours

The EDM process combines precision and safety in a unique way:

![]() High process safety: Possible sources of defects are reduced to a minimum

High process safety: Possible sources of defects are reduced to a minimum

![]() Form stability: The manufactured geometry remains stable without requiring another heat treatment

Form stability: The manufactured geometry remains stable without requiring another heat treatment

![]() Exact shaping: Surface and shaping are exactly to the target values

Exact shaping: Surface and shaping are exactly to the target values

![]() Lower time expenditure due to simplified production process

Lower time expenditure due to simplified production process

![]() Cost reduction

Cost reduction

All other products we manufacture in our organisation are built on this knowhow in process engineering and product development.